An ultra sensitive pneumatic impact Hand

Engraving Tool for Engravers, Jewelers and Artists.

The OMEGA, a larger version of the Air Chasing Graver will be

ready to ship soon. The OMEGA, a larger version of the Air Chasing Graver will be

ready to ship soon.

Designed and made by an

engraver/jeweler/toolmaker who has been building his own

engraving tools for 23 years. The Air Chasing Graver is a precision instrument,

designed for unsurpassed hand engraving and impact control.

A unique feature of the tool is the

lack of an internal spring found in other engraving impact tools. This lack of an

internal spring means a much wider power range (.05 PSI through 50 PSI).

Features:

Same size as a traditional palm push graverImpacts

per minute may be adjusted from 2,520 to an incredible 24,500

Length of stroke can be set from just a few

thousands to 3/8 of an inch

User-adjustable, three position comfort choice for tubing

attachment |

The recently released Air Chasing Graver is the

smallest and most customizable hand engraving impact tool available.

|

Stainless construction

Adjustable idle

Walnut handle with a Lindsay banknote style engraving inset

Hardened piston

Accepts gravers or points with shanks fitting a

.133"dia tool hole |

View computer videos of the Air

Chasing Graver at work, filmed through a microscope.

(Left) Air Chasing Graver. (Right)

1"x 3/4" steel engraving with gold inlays using the Air Chasing Graver. (click for close-up)

The Air Chasing Graver is the smallest hand

engraving impact tool on the market, ideally suited for fine exhibition grade

engraving. The tool is similar in size and feel to traditional non-powered hand

gravers.

Air Chasing Graver pictured next to a traditional palm push graver.

The Air Chasing Graver will idle and oscillate with as little as 1/20th of

a pound of air (equivalent to the air pressure in a toy balloon), to provide the finest microscopic engraving shading

cuts. At the opposite extreme, the Air Chasing Graver can use up to 50 PSI, to

become a powerful metal cutting tool for deep engraving

projects, and to aid the jeweler or artist with hammering control. Length of stroke

and impacts per minute are fully adjustable via an adjusting mechanism in the handpiece.

Impacts per minute range from 2,520 to an incredible 24,500 (this is 20,500 impacts faster

than most other engraving impact tools). This allows the user to set up the tool in

accordance with his own unique preferences and to the type of engraving being

executed. Each one of these tools is produced by Steve Lindsay. They are not

mass produced but are made individually, with the personal attention to quality, materials

and fit that Steve Lindsay gives to all the tools he makes for his own engraving work.

| The Air Chasing Graver can also be used for stippling as

on this knife bolster. A point of needle sharpness is used, and the idle adjustment

set so that the tool is impacting continuously. The point is held loosely on the

surface of the work as the tool impacts. Many dots can be placed in a short time.

For the 24k gold inlay, the Air Chasing Graver was first used with a square graver to

outline the butterfly, and then a flat graver was used to cut out the pocket. Next

an onglette was used to under cut the pocket. Then, 24k gold sheet of .015"

thickness was cut out in the shape of the butterfly and a 1/8" round brass punch was

inserted into the Air Chasing Graver and used to hammer the gold into the pocket. (The

hammering expands the gold, forcing it into the undercuts in the pocket holding the gold

in place). The gold was then block sanded down flush, starting with 400 grit paper

and working up to 2000 grit. The final step was stipple engraving, carried out using

the Air Chasing Graver. See

more photos of the piece. |

|

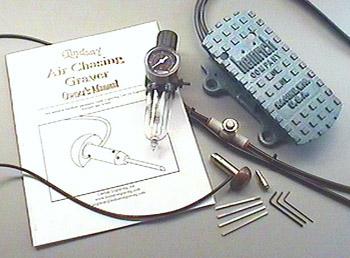

This hand engraving tool is operated and controlled with a

pressure regulator, foot control valve, needle valve, and a port adjustment

mechanism,contained in the handpiece, that controls length and speed of stroke.

Users supply an air compressor. Because the porting is well balanced, air

consumption is efficient. When the tool is idling or impacting delicately the tool

uses just .022 CFM (cubic feet per minute). To put this small amount into

perspective, it would take approximately ten minutes to fill a 10"x11" sized

plastic sack with air at this rate. Maximum air consumption can vary depending on

the porting adjustment set by the user in the handpiece. At 50 PSI, with the porting

adjustment set to a very fast, short length .020" stroke and with the foot control

pushed to the floor, the tool will require .4 CFM. With the porting adjustment set

to the maximum length of stroke of 3/8" the tool will require .875 CFM at the same 50

PSI. This low air consumption means only a small air compressor is required. A minimum of 30

PSI is recommended but 10 PSI is more than sufficient for fine engraving. Steve

Lindsay rarely uses over 15 PSI.

The Air Chasing Graver accepts 3/32" square gravers and 1/8"

round gravers or other gravers and points with a shank fitting the .133" dia. tool

hole. Three High Speed Steel gravers and one Carbide graver are included with the

tool.

No inexpensive aluminum is used in the Air Chasing Graver. The tool

features all stainless construction with a fine finished walnut handle, hardened piston,

adjustable idle, and customizable three

position choice for tubing attachment to the handpiece. Being equal in size to

the traditional non powered palm push graver, the Air Graver fits comfortably in the palm

of the hand. The inset in the butt of the handle is a Steve Lindsay banknote style

engraving designed for the handpiece and reproduced with a restored 1915 150 ton coining

press. The design was engraved in tool steel, hardened, and used to reproduced

itself in the press. Download and view a microscope

video of this actual die being engraved using the Lindsay Air Chasing Graver.

(Above left) Bottom view revealing a screw for the length and strokes per minute

adjustment. (Above right ) Inset banknote style engraving in handle.

(Above) The tubing attachment may be moved to left rear, right rear or to front

center. Above, it has been moved to

front center. More info. and images of these attachment

options

User Feedback about the

Air Graver

Ordering Information

A note from Steve J. Lindsay

The evolution of the Air Chasing Graver began 23 years ago. In

1978 in college I majored in Tool & Die and Mechanical Engineering on the advice given

in 1975 by the late Bruce (James) Meeks, author of the book "Art of

Engraving". While there I made handpieces for myself and my father, Frank

Lindsay, to replace the one that came with a hand engraving machine my father purchased in

1972 from a co-inventor of that machine. In 1979 my father invented a fully adjustable

electronic circuit and valve that produced pulses of air. Other hand engraving

machines currently on the market today work on a similar air pulse principle but use a

mechanical rotary valve to produce the pulses. Both my father and I built numerous

handpieces for his electronic valve invention, until he perfected a miniature handpiece

that I have been using for most of my 21 years in the engraving profession. My

father talked about marketing his invention back then, but he decided not to - he wanted

to give me an edge over the competition in my engraving career.

I have found that the limitation to my father's design and other designs on the market is

that they depend on a spring for either the return or power stroke. The spring in

these designs creates a limited power band. They have an adverse effect of loss of

power, or a complete absence of power when the piston floats, caused by the air pulses

giving insufficient time for the spring to return. This is caused by the frequency

of the air pulses being too fast and/or by too much air pressure in each pulse. For

the past 6 years, I have been drawing, designing, and attempting to create a new device

that would give an even wider range of power and impact strokes, without sacrificing the

finesse and control my father built into his engraving machine. The venture led me

to research electronic solenoid engraving handpieces using 555 timer IC circuits.

These worked for the fine engraving, but did not have much power at the top end and also

produced too much heat. Then there are the drawers full of pneumatic devices and

handpieces including self-oscillating handpieces using a spring for either the return or

impact stroke. I found these designs had a limited power band, vibrated excessively,

and were hard to start without an extra surge of air pressure. Finally, by accident,

I happened on this design. The design I was attempting to build was a two valve

system working together as one in a forward direction, but I found the mechanism ran

better backwards. The challenging aspect was to create an impact device that would

pulsate with the softest whisper of air required for microscopic engraving shading work

and yet be able to muscle out the background around a scroll design when used with much

greater air pressure. This tool has been working well for my engraving and for a few

fellow engraver testers. As more of these tools get out into jewelers' and

engravers' hands I am looking forward to more feedback about

them.

Background and Advantage of the Air Chasing Graver

The traditional tool for hand engraving and stone setting - and one still widely used - is

the palm push graver tool. This traditional hand engraving tool consists of the

working point or graver, set into a wood handle that fits into the palm of the hand.

A problem that arises with this traditional tool, even in very fine

engraving cuts, is that when the graver is pushed through a cut, a loss of control is

experienced due to the force exerted. The graver point will tend to stick and slip

through the cut leaving an uneven incision. Even the best jewelers and engravers

have this problem when using a palm push engraver. Beginners will have even greater

difficulty, and in some cases the slipping can cause extensive damage to the work.

Engraving with a power impact engraving tool can eliminate this problem. No longer

do you need to "push", but let the impacts of the piston drive the tool through

the cut. In fact, while engraving with an impact tool you should not push at all,

but just hold the tool in the cut and concentrate on guiding or steering the graver.

Palm pushing, even with fine cuts, will still result in the sticking and

slipping problem. An advantage of Frank Lindsay's machine, and now the Air Chasing

Graver, is using power for the finest cuts rather than palm pushing. Even when

shading fine lines in something as soft as 24k gold, ivory or pearl, the use of power will

result in more control and confidence than palm pushing. For example, the pearl in this and this

knife handle, were engraved with the Air Chasing Graver set for extremely fine

impacts. Pearl is similar to the consistency and hardness of a fingernail and is

easily cut by palm pushing but, because the sticking and slipping problem can leave an

uneven cut even in soft materials, the handpiece was set up to give short, delicate

impacts by adjusting the speed and length of stroke mechanism within the Air Chasing

Graver. To help the foot pedal control give a full range of movement, the regulator

air supply is lowered 2.5 to 3 PSI. See the engraving tutorial page for

more about this.

User Feedback about the Air Graver

View a microscope video of the Air Chasing

Graver at work.

Ordering Information

The OMEGA, a

larger version of the Air Chasing Graver will be ready to ship soon. The OMEGA, a

larger version of the Air Chasing Graver will be ready to ship soon.

Email: slindsay@lindsayengraving.com

Web: www.lindsayengraving.com

|